With the stress of pre-show marketing efforts, getting your exhibit ready, and organizing show goals, it’s incredibly easy to think you’re done once the show is over. What many exhibitors fail to remember is the importance of dismantling properly – and how a teardown really can affect the ability of using your exhibit components for your next show and saving damages. Here are some of our best practices to keep everything running smoothly and within your budget.

Establish a dismantle plan

Planning for a teardown is difficult and confusing, with crates arriving, trades coming and going and boxes upon boxes showing up needing to be packaged, it’s a mess. A quick plan prior to the dismantling beginning can save a ton of headaches. Here is how we put ours together:

- It’s always a good idea to try to get the same crew that set up an exhibit to dismantle it. Make sure that can happen when you order your labor, and confirm it during the installation with your lead carpenter. It’s easier for guys that have seen the exhibit packed to re-pack it.

- Ensure that return labels are already printed and ready for your lead dismantler.

- Speak with the team to establish where key product and display items are going post show. If brochures, product, or any other elements need to be packed separately, make note of them and make sure everyone is aware before the show closes.

- Plan a logical order of exhibit elements to be dismantled and what trades are needed. Then, look at the timing of the dismantle. Remember, waiting an hour or two until the next day can save you overtime and double time costs. Waiting also lets union employees of all types work instead of sitting around waiting on your ticket.

- Make sure you understand your target move out time and plan for your trucks to check in a few hours before. By understanding the time frame you have, you’ll be able to be more flexible during dismantle.

Make sure everyone knows what’s supposed to be in your crates.

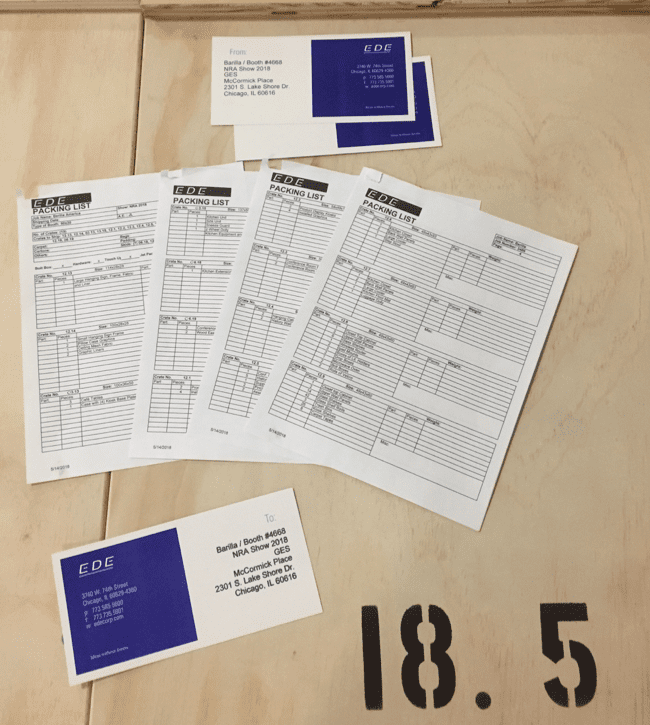

Your packing lists are your keys to organization – your roadmaps to installation and dismantling your exhibit, how it came in is the safest way it should go out. Make sure that your team has the packing lists, printed. As an additional step, our team attaches a physical copy of the photo of each crate’s contents to its door to make sure anyone handling that crate knows exactly what is inside – and what goes inside when it comes time to pack up. Knowing what goes where ensures that your expensive crating is doing its job properly on the long road home.

Ensure you have the right packing materials at the close of the show.

Remember all the foam and packaging material that you tripped over in the aisles during setup? That material was protecting your expensive exhibit components, and you should have the same amount to re-protect it on the way back. Ideally, you have extra packing materials on hand in case something was mistakenly thrown away, but ask your installation crew to bring the material at the end of the show. The cost may seem expensive, but the bill on the way back for damaged exhibit components could be far costlier.

Communication Matters

Sticking around for the close of the show isn’t necessary, but communication is. Make sure that you are in contact with your lead dismantler. Set a list of communication points that you should receive a call or a text on. Our list includes:

- Progress pictures at the close of each day.

- Pictures of the crates – packed, labeled and separated by their destination.

- A copy of the outbound bill of lading (BOL) a few hours before they need to be submitted (in case something is wrong).

- Then a copy of the outbound bill of lading (BOL) after they are submitted to verify shipments are being sent properly.

This list gives you what you need, and lets you make sure that the appropriate ducks are being sorted into their proverbial row.

The importance of a proper dismantle is often overlooked by trade show managers. In the end, an estimated 70% of trade show exhibit damage is the result of shipping damages due to improper dismantling and packing. Being organized and coming into the process with a plan will not only save you money at your next exhibit installation, but add potential years to your exhibit’s lifespan.